Utilizing Laser Cutting Services to Increase Efficiency

Do you know Utilizing Laser Cutting Services to Increase Efficiency? The use of laser cutting technology has completely changed how several industries design and produce their goods. The accuracy and speed of laser cutting have made it the preferred method for companies wishing to effectively produce high-quality goods, from automotive parts to aerospace components. Local businesses in American Fork, Utah, can benefit from this cutting-edge technology by using the laser cutting services that are offered there.

Read More:Issues That Science Has Yet To Resolve

The History of Laser Cutting

Since its inception in the 1960s, laser cutting technology has advanced significantly. The majority of manufacturing applications were impractical for the first lasers because of their size and cost. But as the technology advanced and become more small and affordable, it started to be employed a lot in many other industries.

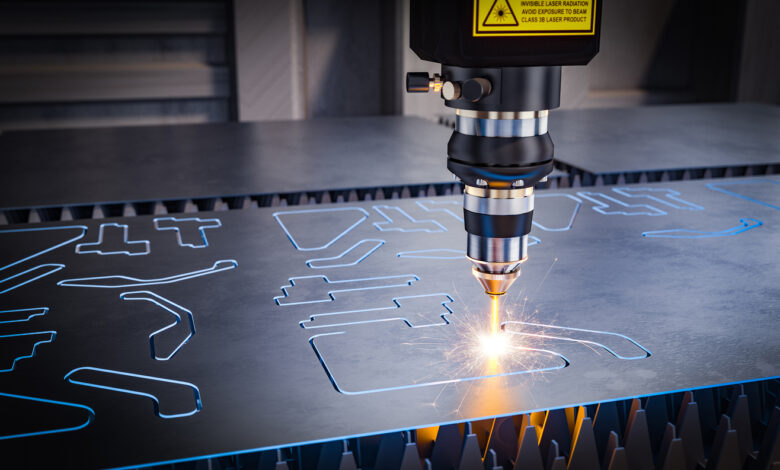

Metal, wood, plastic, and other materials can all be cut using laser technology. Because the laser beam is narrowly concentrated, it can precisely and accurately cut through the material. Laser cutting is also significantly quicker than conventional cutting techniques like machining or sawing due to its speed.

The Benefits of Laser Cutting Services

Both organizations and consumers can profit from employing laser-cutting services. Businesses can easily produce high-quality products because of the accuracy and speed of laser cutting, which lowers production costs and boosts profitability.

Customers also gain from laser cutting since technology makes it possible to produce goods with intricate designs and shapes that would be challenging or impossible to do using conventional techniques. Additionally, laser cutting yields a precise, clean cut with no material waste and no requirement for additional finishing work.

Types of Materials That Can Be Cut

Metal, wood, plastic, and other materials can all be cut using laser technology. Metal is a particularly preferred material for laser cutting because it enables the accurate and precise production of complicated shapes and designs. Lasers can also be used to cut other materials including wood and plastic, albeit the type of laser and the cutting technique may change depending on the substance.

The Laser Cutting Process

Making a design is the first step in the laser cutting process, which is commonly done with CAD software. Following that, the design is transformed into a series of G-code instructions, which direct the laser cutter as it cuts the material. A cutting head, a table, and a laser beam make up the laser cutter. The cutting head directs the laser beam while the cutting material is laid out on the cutting table. The cutting head moves along the cutting path, adhering to the G-instructions, and code’s as the laser beam slices through the material.

Making snow protection for roofs is one industry that might not immediately come to mind when considering laser cutting. Devices called snow guards are put in place on rooftops to prevent snow and ice from sliding off and perhaps causing harm or damage. Since laser cutting enables precision metal cutting and shaping to match the unique requirements of each installation, it is frequently utilized to produce the metal components of snow guards.

Environmental Benefits

Laser cutting provides numerous environmental advantages in addition to its economic advantages. Reduced material waste as compared to conventional cutting techniques is one of the key benefits. The quantity of material lost during cutting is reduced because to the clean, accurate cut that lasers make.

Additionally, laser cutting is more energy-efficient than a lot of other cutting techniques. The laser beam has a reduced carbon footprint than technologies that consume more energy since it uses little electricity. This makes laser cutting a more environmentally friendly option for companies who want to lessen their influence on the environment and their carbon emissions.

Finding a Reputable Laser Cutting Service

Researching and selecting a business with a reputation for dependability and quality is crucial when looking for a laser-cutting service. The following hints will assist you in locating a reliable laser-cutting business in American Fork, Utah:

- – Choose an experienced company: An organization with a lengthy history in the field is likely to have a wealth of experience and expertise. This can be crucial for tasks that are more complicated and call for a higher level of skill.

- – Verify credentials: Seek out a business with accreditations from reputable bodies like the International Organization for Standardization (ISO) or the American Society of Mechanical Engineers (ASME) (ISO). This demonstrates the firm’s dedication to quality and safety.

- – Take into account the tools and technology: For the best outcomes, make sure the business you’ve chosen has the most up-to-date tools and technology. This comprises the software and laser cutting equipment used to develop and carry out the cutting designs.

- – Don’t be afraid to ask questions. Inquire about the experience, tools, and procedures of possible vendors. A trustworthy business needs to be eager to respond to your questions and go over its capabilities with you.

- – Read reviews and request references: Research the business online and contact referrals from previous customers. This can help you get a decent indication of the kind and degree of service you can anticipate.

The Future of Laser Cutting

Many industries, including snow guards for roofs, will probably continue to use laser cutting extensively. In American Fork, Utah, laser cutting can be used to precisely and quickly produce the metal parts of snow guards, resulting in a high-quality finished product. The efficiency and aesthetic appeal of these devices can be further enhanced by using custom snow guards with intricate shapes and designs as technology develops.

Overall, laser cutting will remain a crucial tool for companies in American Fork, Utah, striving to maintain their competitiveness due to its accuracy and efficiency. Laser-cutting services can assist you in achieving your objectives, whether you’re in the automotive, aerospace, or prototyping industries or are just searching for a complex design to be cut precisely.

2 Comments